27 Jan 3D Printing Materials Guide

Check out our 3D printing materials guide to learn about all materials used for home and industrial 3D printing today.

When it comes to 3D printing, the sky is (almost) the limit in terms of what materials you can use — and researchers are constantly making new materials 3D printable.

There are a few main material types used in 3D printing. Most common are plastics, which can range from engineering grade, like PEEK, or very easy to use, like PLA. Resin is another common material and it’s used with SLA printers. Composites are another category and, as the name implies, they’re created by combining two materials to get the best properties of each. The last big group of materials is metals. These are only printable using industrial machines.

Take note: In this guide, we focus solely on commercially available 3D printing materials. That means we have excluded materials from this 3D printing materials guide that you can’t buy off the shelves, like food and bio-materials.

If you don’t have access to a printer, or if you really want to ensure that your pieces are high quality, consider hiring a 3D printing service. To find the best one for your needs, check out All3DP’s Price Comparison Service. We provide real-time prices from a variety of services, including Shapeways, i.Materialise, and Sculpteo!

So, for a complete guide to the different materials you can 3D print with, their applications, properties and technologies, read on.

WHICH MATERIAL SHOULD I USE?

Sorry to say, but it depends. For instance, when 3D printing a food container, you will want to use 3D printing materials that are food-safe, like PETG. If you want to test your design for injection molding on a small scale, you don’t have to use expensive metal since there are thermoplastic options, (Nylon).

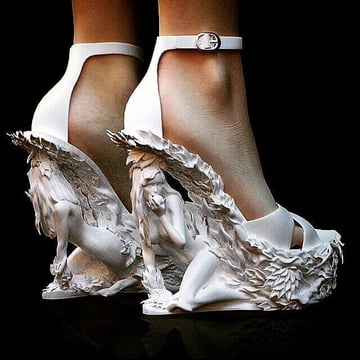

Other additive manufacturing technologies, such as Binder Jetting or Stereolithography, have expanded the spectrum of 3D printing materials drastically. Many tasks have been automated that for centuries lay in the hand of artisans alone. Now, they can be performed by anyone with the proper training in 3D modeling and 3D printing. Take for example the wide range of possibilities for producing full-color concept models, architectural models, and visual arts projects: paper (SDL), sandstone (binder jetting), and resin (PolyJet). So, you could argue that 3D printing materials have led to a democratization of rapid prototyping design concepts.

Metal 3D printing materials have enabled shapes and applications that had been unthinkable before. Now it is a common practice for the aerospace industry to produce complex designs in a singular part that use less material, are lightweight, and as a consequence, use less fuel when compared to traditionally manufactured parts.

PLASTICS

Today, most consumer products are made from thermoplastics. So, this 3D printing materials guide would not be complete without it. This is where plastic 3D printing materials come into play. Designers and engineers prefer to create functional prototypes using 3D printing materials that have the same or very similar properties as the materials used in injection molding, the technology used to create the finished product.

Most of the thermoplastic 3D printing materials can be used in home 3D printing and professional applications alike. The only difference is that professionals are leaning towards Laser Sintering instead of using the Fused Filament Fabrication (FFF).

ABS

Remember the quality of Lego bricks? Then you can relate to why ABS plastic is one the most popular 3D printing materials for desktop 3D printing today.

It is readily affordable, strong and lightweight. ABS filament comes in a broad range of colors. There have been concerns about the fumes that ABS emit when reaching its melting point. If you worry about the toxicity of ABS fumes, there are alternatives like PLA. As ABS is 3D printed at 220°C to 250°C, it is advisable to use a heated printing bed and an enclosed build space to control the cooling of this material and prevent warping. Also, 3D printing materials like ABS filament degrade from humidity in the surrounding air, so store it in vacuum bags or containers.

Learn more about ABS: ABS Filament for 3D Printing – All You Need to Know

Technologies: FDM, Binder Jetting, SLA, PolyJetting

Properties: Strong, light, high resolution, somewhat flexible

Applications: Architectural models, concept models, DIY projects, manufacturing

Price: $

PLA

Another crowd favorite in our 3D printing materials guide is PLA, a cornstarch derivative (but sugar cane and tapioca varieties can also be found), which makes it biodegradable. It‘s an easy material to 3D print with and emits a pleasantly sweet fragrance when heated. For this reason, many people prefer it over ABS. Moreover, it is a suitable 3D printing material for single-use food contact and it contracts less than ABS when cooling. However, PLA is less durable than ABS and susceptible to heat. So, for any type of engineering parts, you’ll be better off with ABS.

PLA is available in a broad range of colors and also comes in a variety of composites, which can give it the appearance of wood or metal, for example. Like ABS filament, PLA degrades from humidity in the ambient air – store it in vacuum bags or containers.

Don’t miss: PLA Filament Buyer’s Guide

Technologies: FDM, SLA, SLS

Properties: Biodegradable, Food safe

Applications: Concept models, DIY projects, functional models, manufacturing

Price: $

Nylon (Polyamide)

Given its flexibility and strength, Nylon is the premier choice for a wide range of applications from engineering to the arts. Often it is simply referred to as “white plastic”. Nylon prints have a rough surface that can be polished smooth. Among FDM filaments, the layer bonding of nylon is stronger than all others, making it the ideal 3D printing material for parts that require good tensile and mechanical strength. Like other thermoplastics, Nylon degrades from humidity in the surrounding air – if you want to use it for home 3D printing, better store it in airtight containers or bags.

Technologies: FDM, SLS

Properties: Strong, smooth surface (polished), somewhat flexible, chemically resistant

Applications: Concept models, functional models, medical applications, tooling, visual Arts

Price: $

PEEK

PEEK is one of the 3D printing materials designed for high-performance parts. Plastics of this family are highly resistant to stress, temperature, and chemicals. But that’s not all: Parts made from PEEK can be exposed to X-ray and gamma radiation. In spite of its robustness, the material is easy to machine and fabricate. But, the catch about temperature resistance is that your 3D printer has to fire up to 400°C in order to extrude this kind of material – a job better left to a professional 3D printing service. Besides the high price, this may be a no-go for you for safety concerns. Owing to their excellent properties, PEEK 3D printing materials are used in the most demanding applications the automotive, aerospace, chemical and medical industries can muster. That includes medical instruments but also semiconductor components.

Technologies: FDM, SLS

Properties: Bio-compatible, highly durable, heat resistant, hard wearing

Applications: Manufacturing (automotive, aerospace, chemical, and medical industries)

Price: $$$

PET

Next in our 3D printing materials guide is PET: The material water bottles are made of. This material is the second alternative to ABS. Unlike ABS, PET does not emit odorous fumes when melted but it is just as strong and flexible. More importantly, PET does not require a heated bed. This material has a glossy finish and is food safe which makes it a popular choice for many consumer products. Store PET 3D printing materials in vacuum bags or containers to protect against humidity.

Technologies: FDM

Properties: Strong, food safe, flexible, smooth surface

Applications: DIY projects, manufacturing, functional models

Price: $

PETG

PETG is a variant of PET that has been combined with glycol to achieve a number of desirable effects for 3D printing such as high transparency. Moreover, PETG 3D printing materials can be printed at lower temperatures while increasing its flow speed (up to 100 mm/s) which in turn translates into speedier prints. PETG components are weather-resistant and are thus often used for garden appliances. Another selling point is its use as a food-safe 3D printing material. When using for home 3D printing, store this material in vacuum bags or containers to protect against humidity.

Don’t miss: 2019 PETG Filament Buyer’s Guide

Technologies: FDM

Properties: Strong, food-safe, weather-resistant, hardly inflammable

Applications: Concept models, DIY projects, functional models, manufacturing

Price: $$

ULTEM

ULTEM is one of the stunning 3D printing materials that is often found in high-performance applications. On the one hand, plastics of this family are highly resistant to stress, temperature, and chemicals, while at the same they also excel by their ease of machining and fabrication. The catch about temperature resistance is that your 3D printer has to fire up to 400°C in order to extrude these 3D printing materials – a job that should not be done at home for safety concerns and can be outsourced to a professional 3D printing service. Due to their robustness, ULTEM 3D printing materials are used in some of the most demanding applications in the automotive, aerospace, chemical and medical industries. You can find the material in electrical connectors, medical instruments, and chip test sockets

Technologies: FDM, SLS

Properties: Bio-compatible, highly durable, heat resistant, hard wearing

Applications: Manufacturing (automotive, aerospace, chemical, and medical industries)

Price: $$$

HIPS

HIPS has two applications: It is often used as a support material in FDM and SLA printing because it dissolves in the chemical Limonene. Since the two share similar properties, HIPS works best when used in conjunction with ABS. But, as the name High-Impact Polystyrene instantly gives away, HIPS is also an extremely durable material that is suitable for shipping containers or other applications that require high impact resistance. Note that HIPS emits vapors when printed, so air the room while using this material on a home printer. Like many other 3D printing materials, it is susceptible to environmental influences, so be sure to store it in airtight containers or bags.

Technologies: FDM, SLA

Properties: Soluble, highly durable

Applications: DIY projects, support material, shipping containers

Price: $

PVA

PVA, like HIPS, is engineered for use as a soluble support material. While other support materials require special chemicals to dissolve, PVA is soluble in tap water. As with most of the other filaments, store it in airtight containers or bags.

Technologies: FDM

Properties: Soluble

Applications: DIY Projects, support material

Price: $

COMPOSITES

Composites are filaments made up of more than one material to take advantage of their best properties. PLA, for example, offers all kinds of composites, from wood to metal. Other composites are geared towards specific industries or functions, like engineering, for example.

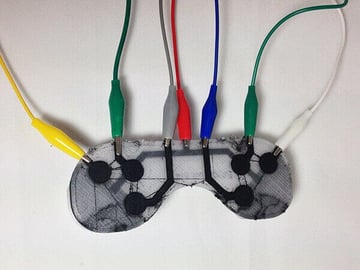

Conductive

A relatively new addition to the filament market, conductive 3D printing materials enable many exciting new design opportunities for the maker community. This stunning material can be used to create touch sensors in applications that require human interface devices like gaming pads and MIDI machines. Other maker projects include conductive traces in wearable electronic devices and creating interfaces between computers, Arduino boards, and other components to build elaborate DIY projects. Conductive 3D printer filament is usually based in either PLA or ABS plastics. Each of which brings the benefits and problems of the original material to the table. Conductive ABS is stronger and more heat resistant than the PLA variant, but it comes with the same fume problems as normal ABS.

Technologies: FDM

Properties: Conductive

Applications: DIY projects

Price: $$$

Metal / Plastic Filament

All of the “metal” filament sold on the market is actually thermoplastic that has been mixed with low amounts of metal. These 3D printing materials allow you to 3D print components that have the optical properties of 3D printed metal. Also, the metal-plastic-filament is heavier than other thermoplastics. Popular composite 3D printing materials include bronze, copper, steel, and iron. Be aware that your 3D printed parts will require post-processing to get the desired metal appearance. Also, be sure your printer nozzle can handle the material.

Technologies: FDM

Properties: Metallic finish

Applications: Visual arts

Price: $$

Alumide

Alumide is a variation of nylon that has been combined with aluminum particles. In terms of durability and physical properties, this material is very similar to nylon. The difference is found in the shiny, durable and porous surface finish. Components printed with alumide have an excellent size accuracy, are tough and suitable for long term use. Alumide and similar 3D printing materials are highly suitable for various post-processing techniques like polishing or coating.

Technologies: SLS

Properties: Strong, heat resistant, high resolution

Applications: DIY projects, functional prototypes, manufacturing

Price: $

Wood

Human curiosity knows no boundaries. So, it was only a matter of time until engineers successfully experimented with adding wood fibers to plastic filaments. Wood 3D prints can be processed just like the real thing. You can cut it, sand it, or paint it. Although this kind of exotic 3D printing material is aesthetically appealing, it does not have the same functional properties as the original material. You shouldn’t build a chair from wood filament, for example.

Interestingly, you can control the shade of brown in you wood filament by setting the extrusion temperature. While 3D printing at lower temperatures will give you a very light shade, high temperatures will result in a strong, dark brown. So, if you want simulate annual rings in your print, vary the print temperature. Depending on your brand of wood filament, your 3D print will also smell like real wood. Some manufacturers offer a broad selection of this exotic material, like birch, olive, bamboo or willow.

Technologies: FDM

Properties: Fragile

Applications: Conceptual models, visual arts

Price: $$

by Max von Übel

Sorry, the comment form is closed at this time.